OEM/ODM Factory Direct Roving - Basalt fiber rebar – Huabin

OEM/ODM Factory Direct Roving - Basalt fiber rebar – Huabin Detail:

Product Profile

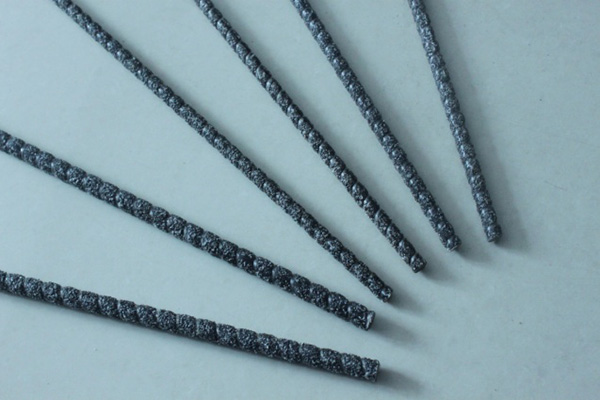

Basalt fiber rebar is formed by pultrusion technology of fiber impregnated resin. The surface of basalt fiber rebar is thread and coated with quartz sand to increase the friction between basalt fibers rebar and the reinforcing medium.

Depend on different resins impregnation, the basalt fiber rebar is divided into:

1. Epoxy resin base basalt fiber rebar

2. Polyester resin base basalt fiber rebar

3. Vinyl ester resin base basalt fiber rebar

Basalt fiber rebar coated different resin, has different tensile strength and used in different environment.

Product Advantages

Due to its raw material - continuous basalt fiber, thus basalt fiber rebar shows perfect properties:

■ Low weight: only 1/4 of the weight of steel rebar based on same diameter.

■ High tension strength: almost 3 times of the strength of steel rebar based on same diameter.

■ Lower thermal conductivity.

■ Good electrical insulation, non-magnetic, electromagnetic.

■ Resistance to corrosion, rotting and warping.

■ No rust

■ Chemical resistance (potash environment, hydrochloric acid, alkali, sea water and other aggressive environments).

■ Easy handling and transportation.

■ High economic

Basalt fiber rebar can replace steel rebar or carbon fiber rebar in some industrial application and in some special complex environments.

Product Application

Due to its performance, now the basalt fiber rebar is widely used into:

■ Concrete reinforcement.

■ Road reinforcement.

■ Marine engineering.

■ Tunnel engineering.

■ Magnetic resonance imaging rooms for health care

■ Military facilities.

Concrete infrastructural

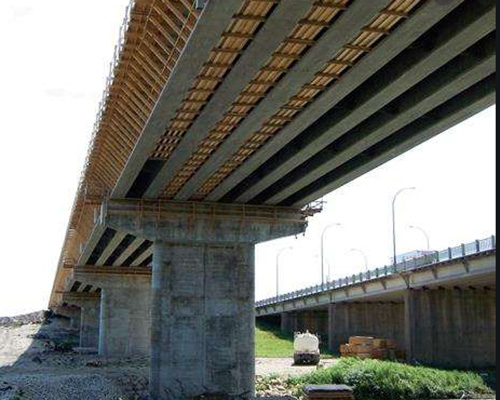

Bridge

Tunnel

Roads

Concrete construction products

Dyke-dam reinforcement

Product Specification

4mm, 6mm, 8mm, 10mm, 12.7mm, 14mm, 16mm, 18mm, 22mm, 32mm are common and popular size, we accept customized.

Product detail pictures:

Related Product Guide:

Being supported by an advanced and specialist IT team, we could give technical support on pre-sales & after-sales services for OEM/ODM Factory Direct Roving - Basalt fiber rebar – Huabin, The product will supply to all over the world, such as: Montpellier, Uruguay, Malawi, With strong technical strength and advanced production equipment, and SMS people purposefully , professional, dedicated spirit of enterprise. Enterprises took the lead through the ISO 9001:2008 international quality management system certification, CE certification EU ; CCC.SGS.CQC other related product certification. We look forward to reactivating our company connection.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.