Quality Inspection for Pultruded Frp Manufacturing - Hardener 2251 – Huabin

Quality Inspection for Pultruded Frp Manufacturing - Hardener 2251 – Huabin Detail:

Product Profile

Hardener 2251 is designed for epoxy resin and it is for heating operation under low temperature.

Technical indicator

|

Technical index |

Data |

|

Viscosity (25℃) |

50-100 |

|

Proportion (25℃) |

0.95 |

|

Amine value (mgKOH/g) |

300 |

|

Active hydrogen equivalent |

87 |

|

Gelation time (25℃/100g)minutes |

75 |

|

Film hardening time (25℃) hours |

6 |

|

Complete hardening time (70/25℃) hours |

18 |

Advantage

■ Low viscosity

■ High glossy

■ Long operation time

■ High mechanical strength

Mechanical property

| Mechanical property | Curing process | |

| Tensile strength | 60.5Mpa | 8hours fully cured at 50-60℃ |

| Bending strength | 96.6Mpa | 5hours fully cured at 70-80℃ |

| Bending failure load | 272N | |

| Tensile failure load | 2702N | |

Product Application

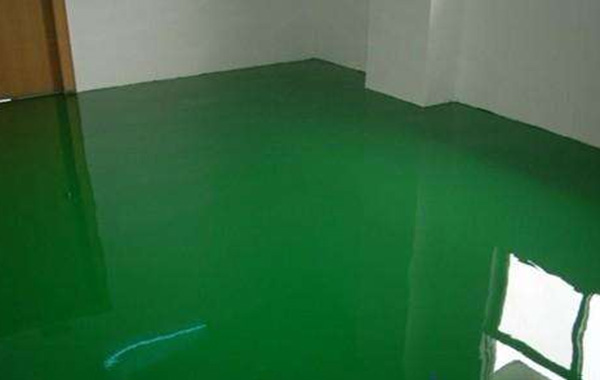

Epoxy floor artesian plane coating/casting material

FRP water softening tank production(winding technology)

Product detail pictures:

Related Product Guide:

We're going to dedicate ourselves to offering our esteemed shoppers with the most enthusiastically considerate solutions for Quality Inspection for Pultruded Frp Manufacturing - Hardener 2251 – Huabin, The product will supply to all over the world, such as: Indonesia, Slovenia, Costa rica, So far our merchandise have been exported to east Europe, the Middle East, Southeast, Africa and South America etc. We have now 13years experienced sales and purchase in Isuzu parts at home and abroad and the ownership of the modernized electronic Isuzu parts checking systems. We honor our core principal of Honesty in business, priority in service and will do our best to provide our customers with high quality items and excellent service.

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.