Quality Inspection for Pultruded Frp Manufacturing - Hardener 2251 – Huabin

Quality Inspection for Pultruded Frp Manufacturing - Hardener 2251 – Huabin Detail:

Product Profile

Hardener 2251 is designed for epoxy resin and it is for heating operation under low temperature.

Technical indicator

|

Technical index |

Data |

|

Viscosity (25℃) |

50-100 |

|

Proportion (25℃) |

0.95 |

|

Amine value (mgKOH/g) |

300 |

|

Active hydrogen equivalent |

87 |

|

Gelation time (25℃/100g)minutes |

75 |

|

Film hardening time (25℃) hours |

6 |

|

Complete hardening time (70/25℃) hours |

18 |

Advantage

■ Low viscosity

■ High glossy

■ Long operation time

■ High mechanical strength

Mechanical property

| Mechanical property | Curing process | |

| Tensile strength | 60.5Mpa | 8hours fully cured at 50-60℃ |

| Bending strength | 96.6Mpa | 5hours fully cured at 70-80℃ |

| Bending failure load | 272N | |

| Tensile failure load | 2702N | |

Product Application

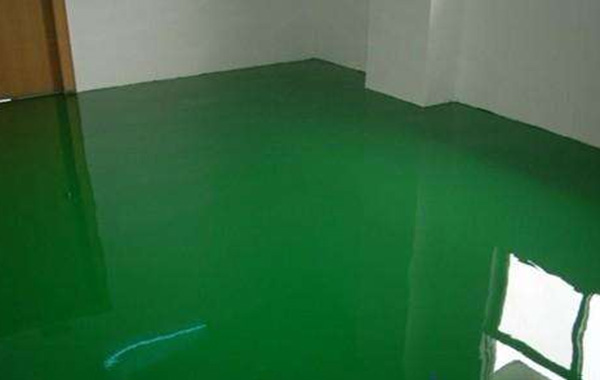

Epoxy floor artesian plane coating/casting material

FRP water softening tank production(winding technology)

Product detail pictures:

Related Product Guide:

Now we have superior devices. Our solutions are exported to your USA, the UK and so on, enjoying a superb name between customers for Quality Inspection for Pultruded Frp Manufacturing - Hardener 2251 – Huabin, The product will supply to all over the world, such as: Brisbane, Slovenia, Greece, We have won a good reputation among overseas and domestic clients. Adhering to the management tenet of "credit oriented, customer first, high efficiency and mature services", we warmly welcome friends from all walks of life to cooperate with us.

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.